what is a ball mill

what is a ball mill

Mills was a calming presence down the stretch of games early last season, frequently slowing things down and ensuring Durant got the ball in his spots. The following play is a great example of this.

Learn More

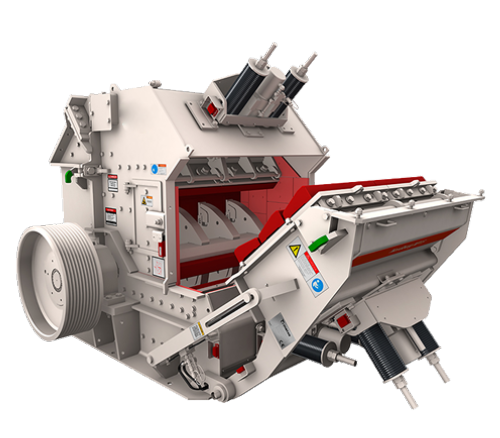

Ball mill is the key equipment for crushing materials after being crushed, so it is widely used in mineral processing, building materials and chemical industries. What is the ball milling

Learn More

Ball milling is a size reduction technique that uses media in a rotating cylindrical chamber to mill materials to a fine powder. As the chamber rotates,

Learn More

Ball mill is a very important mineral grading equipment, which is indispensable for mineral processing, building materials, metallurgy and chemical industry

Learn More

The contact between the steel balls is point contact, and the steel rods of the rod mill are in line contact, so the working characteristics of the two are obviously different. 3. Drainage-mine method Among the ball mills, commonly used are grate ball mill and overflow ball mill, while rod mills have only two types: overflow type and open type.

Learn More

Ball mills are used the size reducing or milling of hard materials such as minerals, glass, advanced ceramics, metal oxides, solar cell and semiconductor

Learn More

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell. The imagery below helps explain what goes on inside a mill as speed varies. Use our online formula

Learn More

1. Ball mill. a Ball mill has a wide range of applications. It can grind metal ore and non-metal ores, which is suitable for hard materials, such as quartz, gold ore, copper ore, iron ore, potash feldspar, etc. b Ball mill is also can be applied in the industries such as cement, construction materials, fireproofing materials, glass, and ceramics.

Learn More

For Sale: 5 beds, 3.5 baths ∙ 4159 sq. ft. ∙ 7545 Ball Mill Rd, Sandy Springs, GA 30350 ∙ $789,900 ∙ MLS# 7111494 ∙ Just steps away from Dunwoody Country Club with views to the golf course from you

Learn More

The equipment secured includes a ball mill, motor and numerous spare parts, and is being purchased from D'Angelo International LLC. The mill being purchased is 13.5' diameter by 20' in

Learn More

What is a ball mill? The ball mill is the key grinding equipment for powder making the crushed material. This type of grinding machine is to put a certain number of steel balls in its drum body as grinding medium, the materials are ground and mixed by the impact of the falling steel balls. ball mill in ore beneficiation production line

Learn More

A ball mill is simply a container that is filled with pebbles (either of porcelain or stones e.g. Flint) into which a charge (powder or slurry) is put and

Learn More

1. Fill the container with small metal balls. Most people prefer to use steel balls, but lead balls and even marbles can be used for your grinding. Use balls with a diameter between ½" (13 mm) and ¾" (19 mm) inside the mill. The number of balls is going to be dependent on the exact size of your drum.

Learn More

R0.25mm-1mm tapered ball end mill 1/8" handle CNC engraving machine woodworking engraving. 1 Ball Nose End Mill. 3D engraving for CNC engraving machine, manual trimming machine, plywood, hardwood, plastic, MDF, carbon steel, Inconel, stainless steel, etc.

Learn More

Ball mill, also known as tumbling or pebble mill is milling equipment that encompasses cylinder-containing balls and is mounted on a

Learn More

Jul 15, · The ball mill is an important equipment in the grinding industry, especially in mineral treatment plants. It is widely used in cement, silicate product, new building materials, fire-resistant materials, chemical fertilizers, black metal, glass, ceramics, etc. WHERE TO BUY & LEARN MORE ABOUT PLANETARY BALL MILLS?

Learn More

A ball mill is a type of tumbling mill which uses hard steel balls for grinding. This coal is fed into the ball mill through a chain feeder, operated by a motor

Learn More

A ball mill, a type of crusher, is a cylindrical device used to grind chemicals or mix compositions. Ball mills rotate around a horizontal axis, partially filled with Ball Mill- Heavy Industry – Crusher & Mill, Jaw Ball Mill is one of the fine mining equipments, which manufactured by Henan Heavy Industry in China.

Learn More

Ball mill Ball mills are mainly used in metallurgy, chemical, electric power, cement and other industrial and mining enterprises to grind various ores and other grindable materials.

Learn More

A ball mill is a cylindrical machine, generally used for mashing and crushing paints, ceramic materials, ores, and other hard materials. By

Learn More

Aug 26, · Ball mill. The ball mill is a device that destroys the raw materials again after they are mined or broken into small pieces to make their particles smaller. From its name, it can be understood that the ball mill is equipped with steel balls in a closed cylinder. Through the rotation of the cylinder, the steel balls fall from high places and

Learn More